Komatsu Tires can be used for manufacturing as of their quality. Tires and rims are the most vital parts of any construction vehicle. They affect the performance, fuel efficiency, and safety of large types of machinery. Although tires are one of the most important aspects to consider while working on a construction site, the tires, which are available in the market, are unreliable. There is a huge difference between cheap and reliable tires and expensive, but low-quality tires.

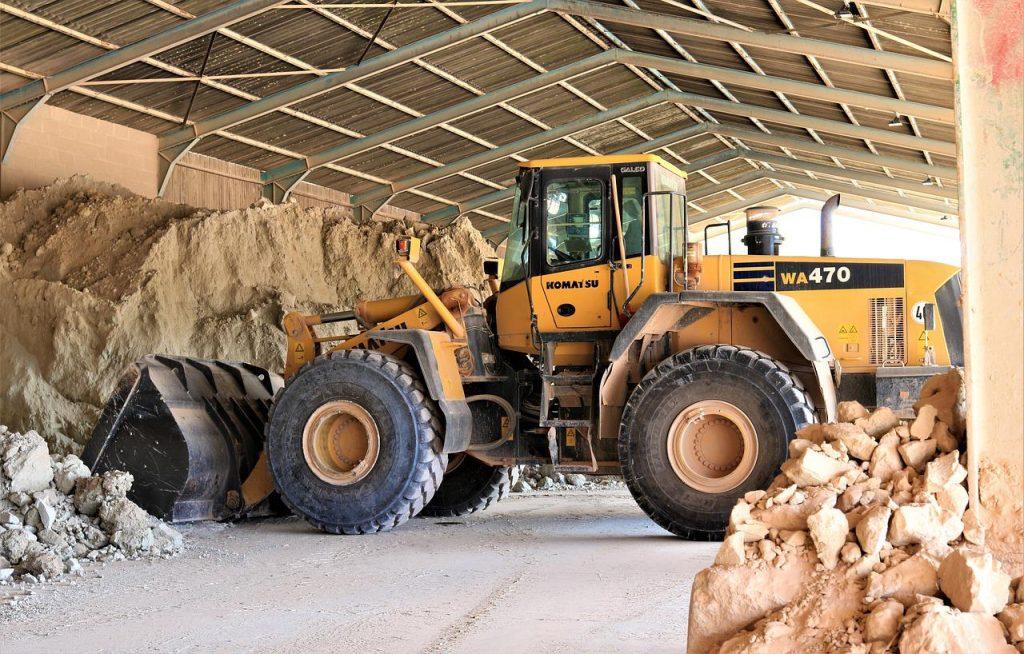

There are numerous kinds of tires available in the market, and it is essential to select the best that maintains good quality, and durability, Komatsu is one of the leading makers of high quality and durable tires. Learn why you should be getting your hands on Komatsu Tires and how you can speed up your work.

Komatsu Tires For Driver Safety:

The latest construction vehicle braking systems are so advanced that they carry a complex network of interlocked mechanical components as well as electronic devices, all of which need to be in good working order. For example, Komatsu Tires have an important job to do because they generate frictional and kinetic energy that’s used to create electricity via regenerative braking – and that helps boost efficiency and performance.

Pressure:

Keeping your tires properly inflated is extremely important for numerous reasons. Underinflated tires are more likely to break down or blow in the case of a puncture than properly inflated ones because they experience much higher temperatures and greater stress. Industrywide measurements have shown that about 90% of blowouts can be traced back to tire underinflation, which is why it’s much less risky to deal with a flat if your tires aren’t underinflated.

Uptime And Fleet Strategies:

Fuel and Komatsu Tires are amongst a fleet’s largest costs – they can be both expensive and wear out at an alarming rate. We do not know the specifics of your project but we understand that productivity has to work with tiny margins now in which case you might be very careful about spending money on tires or fuel due to their high cost.

A tire pressure monitoring system will save you all kinds of time, money, and unnecessary headaches! It would prevent your fleet’s drivers from running out of fuel as well as your tires wearing out faster than they should because they are being kept underinflated by 10% when clearly they could have done twice the mileage had they been properly inflated.

Minimize Your Cost With Komatsu Tires:

Known companies own the global market for Komatsu Tires used in mining trucks. Their experts give advice on the use and performance of their products to the customers. In general, it is recommended that a new tire should first run 1/3 of its lifetime in front positions and then 2/3 of rear life. This has been proven to be beneficial both to the product itself and the machines they are used with, as more even distribution of weight will reflect less usage on every tire set thus prolonging its overall lifespan.

When consulting the different manufacturers of tires for mining trucks, we discovered that the technical suggestion to operate in the ratio 1/3 of the tire life in front positions, has more to do with a matter of reuse of the same for rear positions, that for a technical matter of accumulation of efforts over them. By reusing them in the back positions, although those will cause a significant effort on those tires, it becomes economically viable for companies by getting to pay less each time they need replacement tires which can be up to every 6 months depending on operation hours.

Conclusion:

Komatsu Tires are known for their ability to stand the test of time. Komatsu Tires for mining and drilling applications are no different. Komatsu Tires are one of the best tires in the construction industry. They provide heavy-duty performance that protects both the workers and the machines. Komatsu has become a leader in the construction industry.